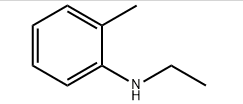

Synonyms: N-ETHYL-O-TOLUIDINE;N-ETHYL-2-AMINOTOLUENE;N-ETHYL-2-TOLUIDINE;N-ETHYL-2-METHYLANILINE;N-ethylChemicalbook-2-methyl-Benzenamine;N-Ethyl-N- (2-methylphenyl)amine;N-ETHYLORTHOTOLUIDINE;N-ETHYL-O-TOLUIDINE97%

CAS number: 94-68-8

Molecular formula: C9H13N

Molecular weight: 135.21

EINECS number: 202-354-3

Related categories: reagents and supplements; aromatic hydrocarbons; intermediates; chemical intermediates; chemical raw materials; raw materials; organic chemical raw materials; organic chemical; Intermediates of Dyes and Pigments

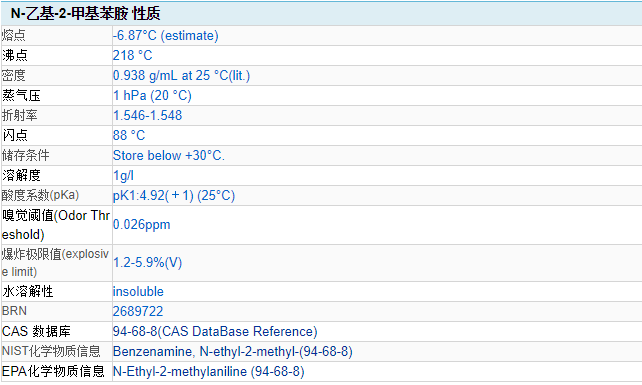

Chemical properties: boiling point 218°C, 95.5°C/1.3kPa, relative density 0.938, refractive index 1.5470, flash point 88°C.

Uses:Intermediate of Youlesan.

Used in dye, medicine and other organic synthesis

Production method :

1. Ethanol alkylation method: Fill a fluidized bed reactor with a capacity of 400 parts with H3PO4-SiO2 catalyst, with an internal surface area of 400m2/g, and a H3PO4 content of 10%. In a quartz evaporator installed in the lower part of the fluidized bed, 110 parts of a mixture of the following composition, namely 66% o-toluidine and 34% ethanol [ratio 1:1.2 (molar ratio)] was evaporated at 250°C. The fluidized bed is heated to 330°C with Chemicalbook. 108 parts of condensate are obtained per hour, of which the content of N-ethyl o-toluidine is 60.0 parts, the content of N,N-diethyl o-toluidine is 10.7 parts, and the content of o-toluidine is 14.5 parts. The conversion rate is 80%, 82.5% of the reacted o-toluidine is converted into N-ethyl o-toluidine, and 13.1% is converted into N,N-diethyl o-toluidine. Alkylating agent ethanol 5% is converted to ethylene.

2. Bromoethane alkylation method? Add 40mL (0.37mol) of o-toluidine and 14mL (0.185mol) of bromoethane into a 250mL three-necked flask. After heating and refluxing for 2h, it is alkalized with 40% sodium hydroxide solution. Then add 18.5g (0.136mol) of zinc chloride and 20mL of water in the Chemicalbook solution, and stir for 2.5h. The filtered solid was continuously extracted with petroleum ether in a Soxhlet apparatus, the extract was washed with dilute ammonia and distilled water, the petroleum ether was evaporated, the residual liquid was distilled under reduced pressure, and the 105~110℃ (4.67kpa) distillate was collected to obtain 21.1g The finished product, calculated as bromoethane, has a yield of 85%.

Category: Toxic

Flammability and hazard characteristics: flammable; combustion decomposes toxic nitrogen oxide gas

Storage and transportation characteristics: the warehouse is ventilated, low temperature and dry; it is stored and transported separately from oxidants, acids, and food

Extinguishing agent: carbon dioxide, foam, dry powder, sand

Post time: May-11-2021