Current situation: the pharmaceutical industry mainly focuses on chemical synthesis pharmaceutical, biological pharmaceutical and traditional Chinese medicine pharmaceutical, and the production has the characteristics of a variety of products, complex processes and different production scales.

The wastewater produced by pharmaceutical process has the characteristics of high pollutant concentration, complex components, poor biodegradability and high biological toxicity.

Chemical synthesis and fermentation pharmaceutical production wastewater is the difficulty and key point in the pharmaceutical industry pollution control.

Chemical synthesis wastewater is a major pollutant discharged during pharmaceutical production [2].

Pharmaceutical wastewater can be roughly divided into four categories [3], i.e. waste liquid and mother liquid in the production process;

Residual liquid in recovery includes solvent, prerequisite liquid, by-product, etc.

Auxiliary process drainage such as cooling water, etc.

Equipment and ground flushing waste water;

Domestic sewage.

Technology for treatment of pharmaceutical intermediate wastewater

In view of the characteristics of pharmaceutical intermediate wastewater such as high COD, high nitrogen, high phosphorus, high salt content, deep chroma, complex composition and poor biodegradability, the commonly used treatment methods include physicochemical treatment and biochemical treatment process [6].

According to the different types of wastewater quality, a series of methods such as the combination of physicochemical process and biological process will also be applied [7].

The picture

1. Physical and chemical treatment technology

At present, the main physical and chemical treatment methods for pharmaceutical production wastewater include: gas flotation method, coagulation sedimentation method, adsorption method, reverse osmosis method, incineration method and advanced oxidation process [8].

In addition, electrolysis and chemical precipitation methods, such as FE-C micro-electrolysis and MAP precipitation methods for nitrogen and phosphorus removal, are also commonly used in the treatment of pharmaceutical intermediate wastewater.

1.1 Coagulation and sedimentation method

Coagulation process is a process in which the suspended particles and colloidal particles in water are transformed into unstable state by adding chemical agents and then aggregated into flocs or flocs that are easy to separate.

At present, this technology is usually used in the pretreatment, intermediate treatment and advanced treatment of pharmaceutical wastewater [10].

The technology of coagulation and sedimentation has the advantages of mature technology, simple equipment, stable operation and convenient maintenance.

However, there will be a large amount of chemical sludge produced in the process of application of this technology, which will lead to low pH of the effluent and relatively high salt content of the wastewater.

In addition, coagulation and sedimentation technology can not effectively remove the dissolved pollutants in wastewater, nor can it completely remove the toxic and harmful trace pollutants in wastewater.

1.2 Chemical precipitation method

Chemical precipitation method is a chemical method to remove pollutants in wastewater by chemical reaction between soluble chemical agents and pollutants in wastewater to form insoluble salts, hydroxides or complex compounds.

Pharmaceutical intermediate wastewater often contains high concentration of ammonia nitrogen, phosphate and sulfate ions, etc. For this kind of wastewater, chemical precipitation method is often used for physical and chemical pretreatment to ensure the normal operation of subsequent biochemical treatment process.

As a traditional water treatment technology, chemical precipitation is often used to soften wastewater.

Due to the use of high purity chemical raw materials in the production process of pharmaceutical intermediate wastewater, the wastewater often contains high concentration of ammonia nitrogen and phosphorus and other pollutants, using magnesium ammonium phosphate chemical precipitation method can effectively remove the two pollutants at the same time, the generated magnesium ammonium phosphate salt precipitation can be recycled.

Magnesium ammonium phosphate chemical precipitation method is also known as struvite method.

In the production process of pharmaceutical intermediate, a large amount of sulfuric acid is often used in some workshops, and the pH of this part of wastewater may be low. In order to improve the pH value of wastewater and remove some sulfate ions at the same time, the method of adding CaO is often used, which is called the chemical precipitation method of quicklime desulfurization.

1.3 adsorption

The principle of removal of pollutants in wastewater by adsorption method refers to the use of porous solid materials to adsorb certain or a variety of pollutants in wastewater, so that pollutants in wastewater can be removed or recycled.

Commonly used adsorbents include such as fly ash, slag, activated carbon and adsorption resin, among which activated carbon is more commonly used.

1.4 air flotation

Air floatation method is a wastewater treatment process in which highly dispersed small bubbles are used as carriers to produce adhesion to pollutants in wastewater. Because the density of small bubbles adhering to pollutants is less than that of water and float up, solid-liquid or liquid-liquid separation is realized.

Air floatation forms include dissolved air floatation, aerated air floatation, electrolysis air floatation and chemical air floatation, etc. [18], among which chemical air floatation is suitable for the treatment of wastewater with high suspended matter content.

Air flotation method has the advantages of low investment, simple process, convenient maintenance and low energy consumption, but it can not effectively remove the dissolved pollutants in wastewater.

1.5 electrolysis

Electrolytic process is the use of impressed current role, produce series of chemical reactions, transforms the harmful pollutants in wastewater and has been removed, the reaction principle of electrolytic process happened in electrolyte solution is through the electrode material and electrode reaction, generate new ecological new ecological oxygen and hydrogen [H] and wastewater pollutants of REDOX reaction makes pollutant removal.

The electrolysis method has high efficiency and simple operation in wastewater treatment. At the same time, the electrolysis method can effectively remove the colored substances in wastewater and effectively improve the biodegradability of wastewater.

The picture

2. Advanced oxidation technology

Advanced oxidation technology, as a new water treatment technology, has many advantages, such as high efficiency of degradation of pollutants, more thorough degradation and oxidation of pollutants and no secondary pollution.

Advanced oxidation technology, also known as deep oxidation technology, is a physical and chemical treatment technology that uses oxidizer, light, electricity, sound, magnetic and catalyst to generate highly active free radicals (such as ·OH) to degrade refractory organic pollutants.

In the field of pharmaceutical wastewater treatment, advanced oxidation technology has become the focus of extensive research and attention.

Advanced oxidation technology mainly includes electrochemical oxidation, chemical oxidation, ultrasonic oxidation, wet catalytic oxidation, photocatalytic oxidation, composite catalytic oxidation, supercritical water oxidation and advanced oxidation combined technology.

Chemical oxidation method is to use chemical agents themselves or under certain conditions with strong oxidation to oxidize the organic pollutants in the wastewater to achieve the purpose of removing pollutants, chemical oxidation methods including ozone oxidation, Fenton oxidation method and wet catalytic oxidation method.

2.1 Fenton oxidation process

Fenton oxidation method is a kind of advanced oxidation method that is widely used at present. This method uses ferric salt (Fe2+ or Fe3+) as catalyst to produce ·OH with strong oxidation under the condition of adding H2O2, which can have oxidation reaction with organic pollutants without selectivity to achieve the degradation and mineralization of pollutants.

This method has many advantages, including fast reaction speed, no secondary pollution and strong oxidation, etc. Fenton oxidation method is commonly used in pharmaceutical wastewater treatment because of the non-selective oxidation reaction in the process of chemical oxidation and the method can reduce the toxicity of wastewater and other characteristics.

2.2 Electrochemical oxidation method

Electrochemical oxidation method is to use electrode materials to produce superoxide free radical ·O2 and hydroxyl free radical ·OH, both of which have high oxidation activity, can oxidize the organic matter in wastewater, and then achieve the purpose of removing pollutants.

However, this method has the characteristics of high energy consumption and high cost.

2.3 Photocatalytic oxidation

Photocatalytic oxidation is a relatively efficient treatment technology in water treatment technology, which uses catalytic materials (such as TiO2, SrO2, WO3, SnO2, etc.) as catalytic carriers to carry out catalytic oxidation of most of the reducing pollutants in wastewater, so as to achieve the purpose of removing pollutants.

Because most of the compounds contained in pharmaceutical wastewater are polar substances with acidic groups or polar substances with alkaline groups, such substances can be directly or indirectly degraded by light.

2.4 Supercritical water oxidation

Supercritical water oxidation (SCWO) is a kind of water treatment technology which takes water as the medium and uses the special characteristics of water in the supercritical state to improve the reaction rate and realize the complete oxidation of organic matter.

2.5 Advanced oxidation combined technology

Every advanced oxidation technologies use there own limitations, in order to improve the efficiency of wastewater treatment, a series of advanced oxidation technologies are grouped together, formed the combination of the advanced oxidation technologies, or a single advanced oxidation technology combined with other technologies into new technology to improve the ability of oxidation and the treatment effect and to meet the water quality changes in larger class pharmaceutical waste water treatment.

UV-Fenton, UV-H2O2, UV-O3, ultrasonic photocatalysis, activated carbon photocatalysis, microwave photocatalysis and photocatalysis, etc. At present, the most widely studied ozone combination technologies are [36] :

Ozone activated carbon process, O3-H2O2 and UV-O3, from the treatment effect of refractory wastewater and engineering application, O3-H2O2 and UV-O3 have greater development potential.

The common Fenton combination process includes micro-electrolysis Fenton method, iron filings H2O2 method, photochemical Fenton method (such as solar Fenton method, UV-Fenton method, etc.), but the electrical Fenton method is widely used.

The picture

3. Biochemical treatment technology

Biochemical treatment technology is the main technology in wastewater treatment, through the microbial growth, metabolism, reproduction and other processes to decompose the organic matter in wastewater, obtain their own needed energy and achieve the purpose of removing organic matter.

3.1 Anaerobic biological treatment technology

Anaerobic biological treatment technology is in the absence of molecular oxygen environment, the use of anaerobic bacteria metabolism, through the process of hydrolytic acidification, hydrogen production acetic acid and methane production and other processes to convert macromolecules, difficult to degrade organic matter into CH4, CO2, H2O and small molecular organic matter.

Synthetic pharmaceutical wastewater often contains a large number of cyclic refractory organic substances, which cannot be directly degraded and utilized by aerobic bacteria, so the current anaerobic treatment technology has become the main means in the field of pharmaceutical wastewater treatment at home and abroad [43].

Anaerobic biological treatment technology has many advantages: anaerobic reactor operation process does not need to provide aeration, energy consumption is low;

The organic load of anaerobic influent water is generally high.

Low nutrient requirements;

The sludge yield of anaerobic reactor is low, and the sludge is easy to dehydrate.

Methane produced in the anaerobic process can be recycled as energy.

However, the anaerobic effluent cannot be discharged up to the standard, and it needs to be further treated by combining with other processes. However, the anaerobic biological treatment technology is sensitive to pH value, temperature and other factors. If the fluctuation is large, the anaerobic reaction will be directly affected, and then the effluent quality will be affected.

3.2 Aerobic biological treatment technology

Aerobic biological treatment technology is a biological treatment technology that uses the oxidative decomposition and assimilation synthesis of aerobic bacteria to remove degraded organic matter. During the growth and metabolism of aerobic organisms, a large number of reproduction will be carried out, which will generate new activated sludge. The excess activated sludge will be discharged through the form of residual sludge, and the wastewater will be purified at the same time.

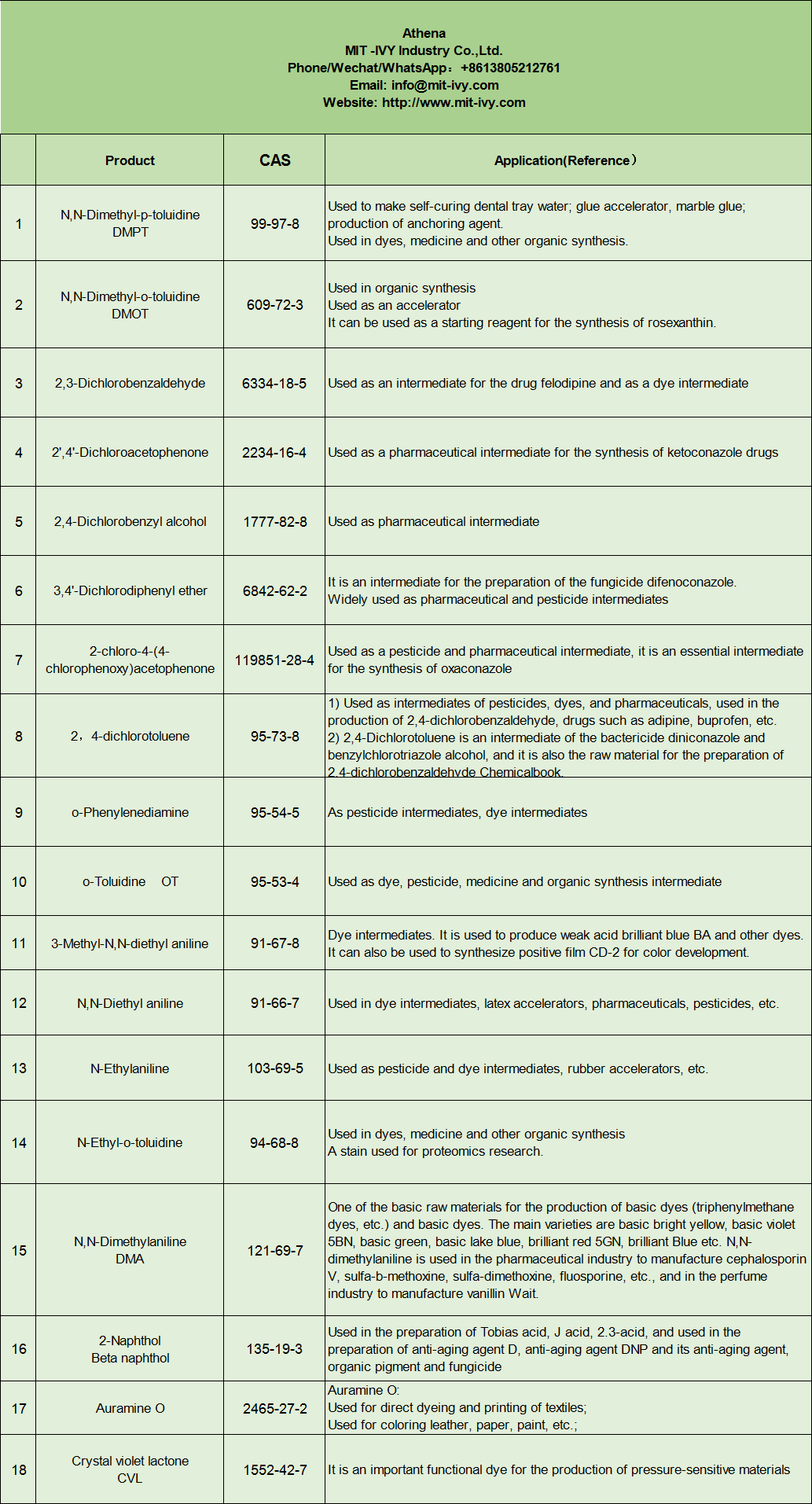

| Product | CAS |

| N,N-Dimethyl-p-toluidine DMPT |

99-97-8 |

| N,N-Dimethyl-o-toluidine DMOT |

609-72-3 |

| 2,3-Dichlorobenzaldehyde | 6334-18-5 |

| 2′,4′-Dichloroacetophenone | 2234-16-4 |

| 2,4-Dichlorobenzyl alcohol | 1777-82-8 |

| 3,4′-Dichlorodiphenyl ether | 6842-62-2 |

| 2-chloro-4-(4-chlorophenoxy)acetophenone | 119851-28-4 |

| 2,4-dichlorotoluene | 95-73-8 |

| o-Phenylenediamine | 95-54-5 |

| o-Toluidine OT | 95-53-4 |

| 3-Methyl-N,N-diethyl aniline | 91-67-8 |

| N,N-Diethyl aniline | 91-66-7 |

| N-Ethylaniline | 103-69-5 |

| N-Ethyl-o-toluidine | 94-68-8 |

| N,N-Dimethylaniline DMA |

121-69-7 |

| 2-Naphthol Beta naphthol |

135-19-3 |

| Auramine O | 2465-27-2 |

| Crystal violet lactone CVL |

1552-42-7 |

MIT –IVY Chemicals Industry with 4 factories for 19years, dyes Intermediates & pharmaceutical intermediates &fine &specialty chemicals . TEL(WhatsApp):008613805212761 Athena

Post time: Apr-25-2021