Alkyd mixed paint/Water-based protective paints/Waterborne Epoxy Industrial Protection Paint

Product introduction

The product is based on waterborne alkyd resin as the main film forming material, the film gloss is high, fullness is good.

No toluene, ethylbenzene, xylene and other benzene series, low VOC, formaldehyde, heavy metal content lower than the national standard, no irritating odor, no harm to human body; 3. Normal temperature drying or low temperature baking, strong film adhesion, good compatibility with various water-based topcoats and solvent topcoats; Excellent rust-proof, anti-corrosion performance.

Details

| 1 | substrate treatment: simple removal of oil and rust can be constructed. |

| 2 | Construction method:

(1) brush coating, roll coating, spraying and dip coating. (2) Spraying is recommended. It is recommended to add 5%-20% water. It is suitable for spraying viscosity (40-60S, 25 ℃, 4# cups) at construction site. |

| 3 | construction conditions:

In the air relative humidity less than 85% weather construction, to avoid rain, snow, fog, windy weather, painting temperature is 5 ℃-40 ℃ |

| 4 | construction process:

(1) Add appropriate amount of water to the paint, stir evenly, so that the viscosity is between 40-60S; use 80-120 mesh screen to filter, to be used; (2) Hanging the processed workpiece with a hanger, then adding the paint to the spray gun, the spray gun pressure is controlled at about 0.2-0.4 Mpa. The paint can be baked at low temperature. After 10 minutes of leveling, it can be baked at 80-100 (?) C for 15 minutes. (3) after the first stop, the 12h can be sprayed second times after natural drying. (4) After the workpiece is sprayed, the redundant paint in the spray gun bucket is poured back into the paint barrel. If it is not used for a long time, the paint barrel should be sealed to prevent moisture evaporation and crust. (5) clean the spray gun with clean water to prevent clogging. (6)natural drying 24h or low temperature baking requirements are finished. After the workpiece is cooled, the workpiece is packed and put into storage. |

Packaging:

Major Primer A: 30kg/container

Curing Agent B: 3kg/container

| Product Description | HD-158, high solid epoxy zinc rich anti-corrosive primer, is composed of two-component metal protective primer composed of epoxy resin, zinc powder, polyamide, etc. |

| Product Feature | High solid coating with high zinc content.

Excellent anti-corrosion and cathodic protection. Meet the composition requirements of SSPC PRIMER 20 and HG/T 3668-2009. |

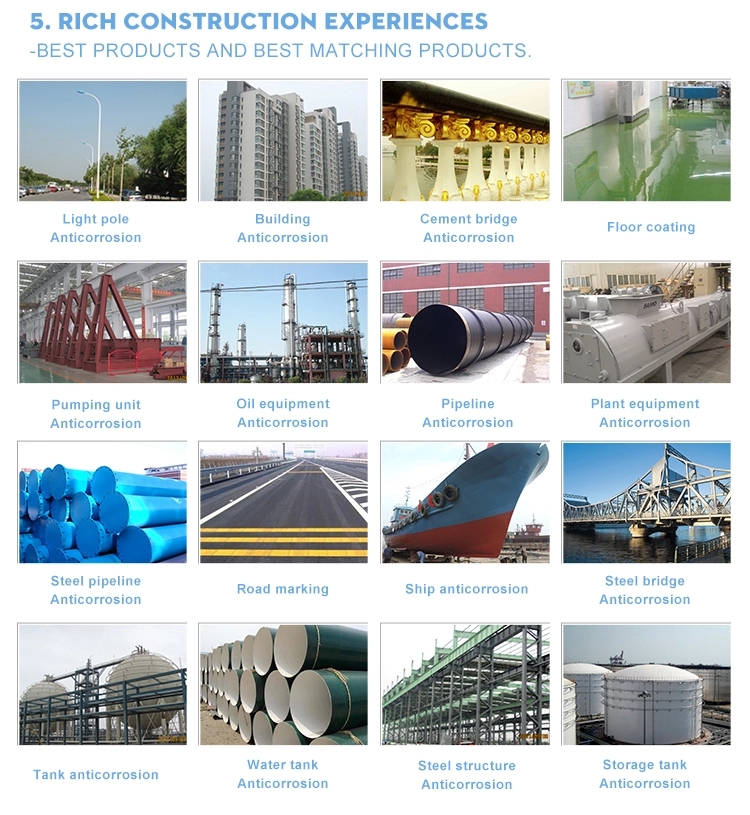

| Recommended Use | Suitable to use as long-term protective primer on the parts which exposure to C5-I or C5-M (ISO 12944-2) high corrosion environment, such as petrol storage tank and equipment, power station, bridge, marine facilities, steel structure, port machinery, outdoor equipment etc. It is long-lasting anti-corrosion in combination with other coatings. |

Application

Suitable for decorative finish with high gloss requirements, supporting water-based sourdough primer. Suitable for gantry crane, trailer, car chassis parts and other working conditions.

Petrochemical equipment, doors and windows, fences, radiators, automotive chassis, water pumps, agricultural vehicle parts, etc., anti-corrosion coating on the surface of metal facilities.

Construction description

1. Clean the oil, rust, old patent leather and other dirt on the surface of the substrate before painting to ensure that the surface of the substrate is clean and dry.

2. Grinding wheel is used to remove welding bumps, spatter, and hardened layer on the workpiece surface. All free edge acute angles after gas cutting, shearing or machining should be polished to R2.

3. Sand blasting to Sa25 level or power tool cleaning to St2 level, construction within 6 hours after sand blasting

4. It can be constructed by dramatic coating and spraying method, and the paint should be stirred evenly before painting. If the viscosity is high, an appropriate amount of deionized water can be added, and the amount of water added should not exceed 10%, and it should be stirred while adding to ensure that the paint is uniform.

5 Maintain good ventilation during construction. Do not work when the ambient temperature is lower than 5C or the humidity is greater than 70%

6. Rain, snow and fog weather can not be constructed outdoors, such as construction, can be taken to protect the paint film by covering it with tarpaulin.

Construction Environment

The construction site should be well ventilated and dusted to ensure construction quality.

The construction environment should be not less than 5' and relative humidity should be <70%.

The temperature of the substrate should not be less than 5', and the well should be more than 3℃ above the dew point of the air.

Cleaning of tools After construction, the tools should be immediately rinsed with water to prevent dryness, and the remaining paint should be kept in a closed place.

Storage and transportation

1. The product should be sealed and stored in a dry and well-ventilated warehouse with a storage temperature above 5 ° C and below 35 ° C to prevent direct exposure to water and sunlight, isolate the fire source, and stay away from the heat source.

2. If the product meets the storage conditions, the storage period is one year from the date of production, and the storage period can be tested beyond the storage period. If it meets the standards, it can still be used.

3. During the transportation process, the product should be prevented from cold, rain and sunlight exposure, and should comply with the relevant provisions of the transportation department.

Caution

1. This product should not be mixed with any oil-based paint or organic solvent.Avoid contact with organic solvents and water before the paint is completely dry, and do not press or rub heavily to avoid destruction of paint film. If the recoating time is too long, it is easy to cause secondary pollution. If the repainting time is too long, it is easy to cause secondary pollution, and must be polished before repainting.

2. workers should wear necessary labor protective equipment.

Store in a dry and ventilated place (5-40℃) for 12 months, after this period, it can still be used after inspection.

Loading and unloading should be done carefully and gently to avoid collision and leakage.

Packing specification: 20kg or 50kg in general. Iron drum or plastic drum. (Packed in different specifications according to user requirements)

Safety and health The following measures shall be guaranteed during construction.

3.Avoid contact with skin and eyes. If the water-based paint comes in contact with skin, wash with warm water. If the water-based paint comes in contact with the eyes, wash with warm water.

Flush well with plenty of water and get medical attention immediately.

Keep out of reach of children.

Observe all health and safety regulations on site.

For detailed information on health and safety and precautions for use of this product, consult the technical instructions.