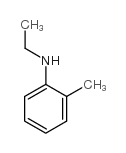

H201 Water-based silver powder paint

Product introduction

The special new port is always in the question, cloud ion water, water-based auxiliary M, high performance wrapping, and environmentally friendly filler on the customer group. It does not kill home, benzene, xylene and other organic solvents. Benzene, xylene and other organic solvents.Made of special water-based resin, imported water-based silver paste, functional additives and other materials, refined by advanced technology, it has the characteristics of high hardness of paint film, good weather resistance, excellent adhesion to different metal base materials, and good adhesion to primer.

Product Application

1.Durable Moisture and Chemical Resistant Film

2.Low Odor

3.Low VOC and HAPs Free

4.Formaldehyde Free

5.Quick Dry

6.Quick Stack Time

7.Excellent Film Building Properties

8.Excellent Flow and Leveling

9.Minimum Grain Raise

10.Resists Yellowing

11.Meets KCMA Performance Requirements, When Applied to Manufacturer’s Specifications

12.24 Hour Pot Life-Can Be Re-Catalyzed Once

Recommended use for storage tanks, rail transportation, functional vehicles, power facilities, transformers, distribution cabinets, machinery and equipment such as high anti-corrosion and decorative coating.

Details

Details

Technical parameters Drying time (25'℃) Surface drying 1 hour

Hands-on 24 hours

Drying 1 hour (60-80°C)

Fully cured 7 days

Gloss ≥80% (60°)

Film hardness H

Paint film adhesion level 4

Paint film flexibility 2mm

Impact resistance of paint film 50cm-kg

Artificial aging resistance 1000h

Methods of application

The first step is to apply MyCover as a primer sealer so that later MySealant 2K, as a two-component water-based polyurethane varnish, creates the perfect protective film. You must wait 4 hours after the application of MyCover.

MySealant 2K is applied on the microcement coating in two layers and the drying time between layers is from 8 to 24 hours, depending on environmental conditions and taking into account that humidity delays drying. After the first layer, the surface should be sanded with a 400 grit sander, while the final layer does not require any sanding.

It should not be applied in environments with a temperature that is below 15ºC and for optimal results it is advisable to apply it at temperatures ranging between 18 and 24ºC. The polyurethane varnish can be applied with a fiber roller or gun.

Advantages

1. High hardness, high wear resistance, high fullness

2. Good rust resistance and long salt spray resistance:

3. Strong adhesion, explosion-proof skin to prevent cracking and falling off

4. Strong water and weather resistance, long-term protection:

5. Reduce emissions and protect the environment;

6. Can be brushed with rust, saving time and effort;

7. Reduce material cost by more than 50% :

8. Reduce storage and transportation costs and eliminate fire hazards;

9. Reduce labor costs and eliminate occupational hazards;

10. The bottom side is integrated, easy to use.

Construction description

1, brush coating, spraying method can be used to construction, the paint should be mixed evenly before painting, if the original paint viscosity is high, can be appropriate to add a small amount of water, add water should not exceed 10%, should be added while stirring to ensure uniform paint;

2, the coating surface should be removed paint, dust, rust and other debris, if necessary, can be scraped putty, to dry, grinding flat:

3, after construction, the paint film can be self-drying, but also low temperature drying, self-drying drying conditions should not be less than 10C, humidity is not higher than 70%; The drying time of room temperature is not less than 15 minutes, and the baking temperature is 60C, not less than 25 minutes.

4, during the construction, it is strictly prohibited to mix with other paints and organic solvents to prevent deterioration, at the end of the construction, all appliances should be immediately washed with water to prevent dry solid, the remaining paint should be sealed and stored, if there is a dry skin, affecting the use, can be filtered with 100 mesh before use.

5. Clean the oil, rust, old patent leather and other dirt on the surface of the substrate before painting to ensure that the surface of the substrate is clean and dry.

6. Grinding wheel is used to remove welding bumps, spatter, and hardened layer on the work piece surface. All free edge acute angles after gas cutting, shearing or machining should be polished to R2.

7. It is recommended to phosphating the substrate to achieve a better spraying effect.

8. Brush painting and spraying can be used for construction, and the paint should be stirred evenly before painting. If the viscosity is high, an appropriate amount of deionized water can be added, and the amount of water added should not exceed 10%, and it should be stirred while adding to ensure that the paint is uniform.

9. After painting, it should be levelled at room temperature for 3-5 minutes before entering the oven, and the temperature should not be adjusted to 140℃ immediately when baking. It is recommended to bake at 50℃ for 10 minutes and at 140℃ for 20 minutes

Surface treatment

1. The surface must be clean and dry, and the surface treatment of the substrate must meet the requirements.

2. The tools used in the construction must be dry and clean. 3.

3. it is forbidden to contact with acid and alkali during the process of paint preparation and coating. .

4. the painting interval must be strictly controlled, when the temperature is 25'C, the painting interval shall not be less than 12 hours.

5. Can not paint thick, a film can not exceed 40μm or will bubble.

6. Construction and drying and curing during the relative humidity is not greater than 75%, the temperature can not be less than 0 ℃ C, otherwise the film can not be completely cured influence.

- This product must be cured for 7 days after painting before delivery.

8.Keep good ventilation and wear necessary protective equipment at the construction site.

Health and Safety This is a water-based product and poses no health hazard under normal use.

It must be well ventilated during use.

Avoid excessive skin contact.

Transportation and storage

1. The product should be sealed and stored in a dry and well-ventilated warehouse with a storage temperature above 5 ° C and below 35 ° C to prevent direct exposure to water and sunlight, isolate the fire source, and stay away from the heat source.

2. If the product meets the storage conditions, the storage period is one year from the date of production, and the storage period can be tested beyond the storage period. If it meets the standards, it can still be used.

3. During the transportation process, the product should be prevented from cold, rain and sunlight exposure, and should comply with the relevant provisions of the transportation department.

FAQ

Q. Are you factory or trading company?

A. We are a factory located in Fuan city, Fujian province, China .

Q. Are all colors are same price?

A.No, the price are different depend on the texture, availability, Ingredients and So on.

Q. Can you provide samples for quality checking before placing an order?

A. Samples are available upon request, but the shipping cost should be paid by customer.

Q. Is there a discount?

A. The discount will be given by the quantity.

Q. How about delivery time?

A. About 7-15 days after payment confirmed.

Q. What kind of payment terms you can accept?

A. We accept T/T, LC, Western Union and Paypal.

-2-300x225.jpg)