Water Based Metal Baking Enamel Paint

Product introduction

Product features

* No free TDI, no added heavy metals

* Excellent mechanical properties, good adhesion

* Toughness, anti-adhesion

* High gloss and good weather resistance

* The film is full and the color is bright

* Dilute with 20-30% clean tap water directly, saving more than 30% of petroleum solvent

* Safety, environmental protection, occupational health protection

Application

Suitable for export automobile and agricultural equipment body, cargo box, bumper.

Export small mechanical and electrical equipment and construction machinery and other metal heavy substrate fields.

Construction conditions

Ambient temperature and base surface temperature should be between 10 ~ 35℃ coating. Choose the right construction method and the right construction tools.

After painting should be at room temperature leveling 3 to 5 minutes before entering the drying room, baking temperature should not be immediately adjusted to 130℃.

It is recommended to lower the first and then high, the recommended procedure is 50℃10 minutes, 130℃20 minutes.

Packing specification

20kg/barrel

Transportation

Transport as non-dangerous goods

Storage

This product should be stored in 5-35 ℃, cool, clean, dry place

Storage life is six months

Note

1. This product is water-based paint, can not be mixed with organic solvents or solvent based paint.

2. Mix well before use and adjust viscosity with appropriate amount of water.

3. When diluting this product, gradually add water to dilute to construction viscosity.

4. Soak the new brush in a mixture of washing powder and baking soda before use, and then rinse with clean water.

5. Wash tools with water immediately after use.

| Standard parameters of water-based amino baking paint | ||||

| Items | Indicator | |||

| water based amino baking varnish | water based metal baking enamel paint | water based amino baking primer | ||

| Status in the container | No abnormality | No hard lumps after stirring and mixing , uniform status. | No hard lumps after stirring and mixing , uniform status. | |

| Storage stability [(50±2)℃, 7d | No abnormality | |||

| Non volatile content, %≥ | 50 | 55 | 60 | |

| Fineness,μm ≤ | 20 | 50 | ||

| Appearance of paint film | flat and smooth | flat and smooth | flat and matte | |

| Drying time/min, 150℃ ≤ | 30 | 30 | 30 | |

| Bending test/mm ≤ | 1 | |||

| Impact resistance/cm ≥ | 50 | |||

| Cross-cut test/grade ≤ | 1 | 1 | ||

| Gloss (60°)/unit value | agreed | |||

| Hardness (pencil) ≥ | 2H | |||

| Water resistance (50±1℃, 24h) | No abnormality | |||

| Salt water resistance (3%, NaCl, 96h) | No abnormality | |||

| Gasoline resistance,93#gasoline,24h | No abnormality | |||

Construction description

1. This product can be air gorge coating, brush coating, silver coating.

2 before use, first touch the paint residue mix evenly, different construction methods add different amounts of water, air diaoxiao add about 5%-15% water dilution.

Add about 10% water dissipation release to the brush coat, and add it as you set, to ensure the book is evenly spread, and filter the air bubbles with 100 mesh.

Filter out the net before construction.

3. It is forbidden to mix with other paints, organic solvents, strong acids or strong alkalis.

The construction environment and other explanatory data are the same as "H901 waterborne antirust paint", please refer to.

Construction environment

The construction site should be well ventilated and dusted to ensure the quality of construction.

The construction environment should be at least 5' and relative humidity should be <70%.

The temperature of the substrate should not be less than 5', and the well should be more than 3℃ above the dew point of the air.

Cleaning of tools After construction, the tools should be immediately rinsed with water to prevent dryness, and the remaining paint should be kept in a closed place.

Surface treatment

Surfaces to be painted must be clean, dry, and free of dirt, dust, grease, oil, soap, wax, scaling paint, water soluble materials, and mildew. Remove any peeling or scaling paint and sand these areas to feather edges smooth with adjacent surfaces. Glossy areas should be dulled. Drywall surfaces must be free of sanding dust. New plaster or masonry surfaces must be allowed to cure before applying base coat. Cured plaster should be hard, have a slight sheen and maximum PH of 10; soft, porous or powdery plaster indicates improper cure. Never sand a plaster surface; knife off any protrusions and prime plaster before and after applying patching compound. Poured or pre-cast concrete with a very smooth surface should be etched or abraded to promote adhesion, after removing all form release agents and curing compounds. Remove any powder or loose particles before priming. Wood substrates must be thoroughly dry.

Priming: New surfaces should be fully primed, and previously painted surfaces may be primed or spot primed as necessary.

Caution

1. This product should not be mixed with any oil-based paint or organic solvent.

Avoid contact with organic solvents and water before the paint is completely dry, and do not press or rub heavily to avoid destruction of paint film. If the recoating time is too long, it is easy to cause secondary pollution. If the repainting time is too long, it is easy to cause secondary pollution, and must be polished before repainting.

2. workers should wear necessary labor protective equipment.

Store in a dry and ventilated place (5-40℃) for 12 months, after this period, it can still be used after inspection.

3.Loading and unloading should be done carefully and gently to avoid collision and leakage.

4.Packing specification: 20kg or 50kg in general. Iron drum or plastic drum. (Packed in different specifications according to user requirements)

5.The following measures shall be guaranteed during construction.

Avoid contact with skin and eyes. If the water-based paint comes in contact with skin, wash with warm water. If the water-based paint comes in contact with the eyes, wash with warm water.Flush well with plenty of water and get medical attention immediately.

6.Keep out of reach of children.

7.Observe all health and safety regulations on site.

8.For detailed information on health and safety and precautions for use of this product, consult the technical instructions.

Company Information

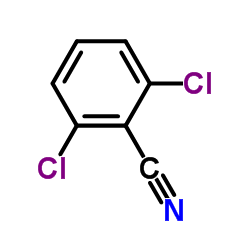

MIT-IVY INDUSTRY CO.,LTD is a manufacturer and exporter of fine chemical dyes & pharmaceutical intermediates in China.

Mainly produce aniline series products and chlorine series products.

MIT –IVY Chemicals Industry Co.,Ltd. is a leading manufacturerof chemical for 21 years with complete production equipment and meticulous management and maintenance of machinery.

We use advanced production technology and test methods to realize production, quality controlling to meet the standard. We have been approved by SGS, ISO9001, ISO140 01, GB/HS16949 and T28001.

Mit-Ivy main products include as the following:

API, pharmaceutical intermediates ,Dye intermediates, fine,speciality chemicals,Waterborne industrial paint and new energy materials.

Our main markets includes America, India, Africa, Indonesia, Turkey, South-east Asia, West Asia and so on. MIT-IVY Industry Main products shares 97% of the domestic market specializing in the production and management, We can supply the products with more competitive cost. with premium quality and price and welcome to consult. Our company has professional persons who major in chemical R&D and sicentific management, supply fine chemical products with high quality and close service, also supply custom-tailored products according to our clients’ requirement. We have a positive and self-motivated management work team with a common philosophy, caring and commitment through teamwork, our team strive to achieve success in delighting our clients and ourselves. we continuously innovate our products and improve our service, sales network. Hence, we initiate the first sale mode on net in China, which is the retail trade of small package bring along wholesale of diversified management modes. Our products are exported widely to South Korea, Vietnam, Australia, Europe and South America, highly recommended by our clients. We insist on the management creed “Market is our compass, Quality is our life, Credit is our soul”. Clients’ trust is our forward powder, their satisfaction is our struggling goal.

Brand Customer Service:

Our JIT customer service account team network in China develop and implement tailor-made concepts for the optimum supply of our customers with industrial and specialty chemicals.

Your advantages:

● Centralized customer service supports simplification of administrative procedures, resulting in time and cost saving.

● Our Chinese network and sophisticated logistics solutions ensure that chemicals of identical quality are supplied to customers with several manufacturing locations and contribute to security in planning and reliability of processes.

● Our processes are continuously optimized and adapted to our customers’ changing structures and requirements.

Superiority of Chemistry Logistics service:

Chemical logistic service is very professional and should be superior under UN regularity, especially for DGR Class series. We provide a special-purpose solution to optimize logistic and suitable packing group and labeling service for our principals. Our main Chinese ports with DGR chemical warehouses are to operate specialty chemical and apply all relative paperwork concerned.

Our distribution capabilities include:

● Flexible deliveries, intelligent solutions

● Anything from bulk shipments of thousands of tonnes down to the smallest shipment of packed goods and even samples.

● Bulk – storage and transport of powders and liquids – movement of goods in ships – powders and bulk liquids

● Pharma, feed and food storage to accredited standards

● Segregated materials by business unit and hazard classification

● Temperature controlled storage and transport

● Effective cost control

● Re-packing, drum filling, bagging, ripping and tipping

● Customer delivery KPI's on delivery fulfillment performance

If you are interested in getting more quotations,

please add WHATSAPP:0086-13805212761 or E-MAIL:info@mit-ivy.com