H602 Waterborne epoxy primer

Product introduction

Two-component water-based epoxy paint.This product is made of water-based ring carrier nozzle, water-based additives, environmentally friendly antirust filler, water-based epoxy coating agent, deionized water, etc. by special process, A, B two-component independent packaging.Waterborne Epoxy Primer is a two-component, low VOC, HAP-free, fast curing water-based epoxy primer coating. It has been engineered to provide excellent adhesion for Chemsol Non-Slip products.It is suitable for use on flooring, ramps, steps, and other areas where priming is recommended prior to application of Chemsol Non-Slip or other topcoats. It is suitable for industrial, commercial, marine, and consumer environments. It is easy to apply and has very little odor which makes it ideal for use in odor-sensitive areas both indoor and outdoor. It is designed to adhere to a variety of porous surfaces including concrete, wood, tile (prepared to expose porosity of the tile) and other surfaces. Priming is recommended for best performance of topcoats.Waterborne Epoxy Primer has been formulated to meet the strict requirements of South Coast Air Quality Management District Rule 1113.

Recommended use:

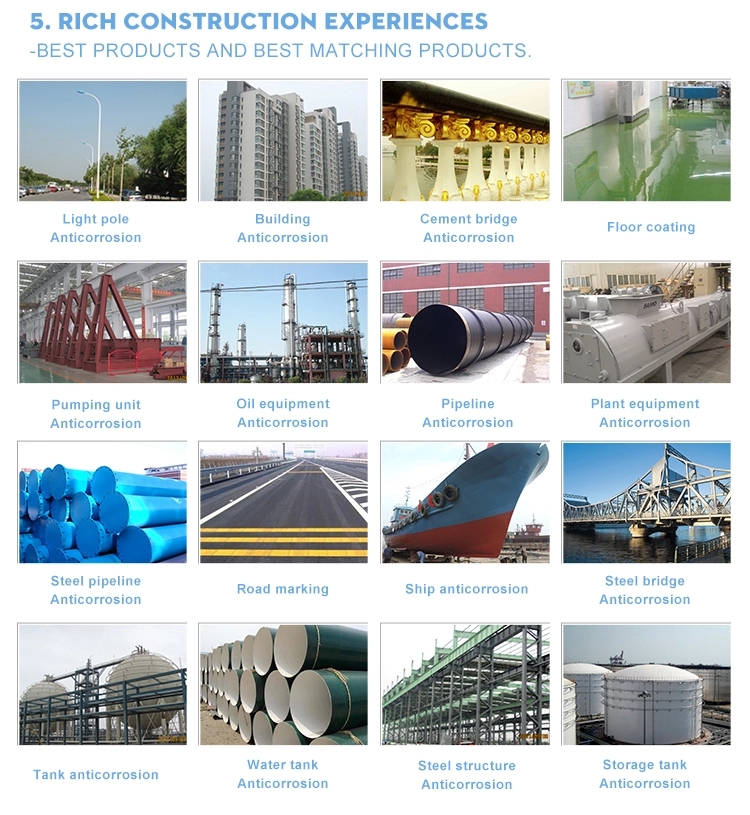

Anti-corrosion coating on the surface of underground pipes, construction machinery, electric power facilities, mining equipment, chemical equipment, construction steel and other steel. Surface coating of automobile parts such as axles.Anti-seepage coating on cement, metal products, aluminum products, FRP surface coating.

Product Application

Waterborne Epoxy Primer is a high technology epoxy coating that is suitable for commercial and industrial use. Thus, installation by professional epoxy installers is recommended. As with most high performance coating systems, the performance, durability, and overall efficacy of this product depends highly on correct surface preparation as well as on correct product application procedures. If surface preparation and/or application procedures are not followed, the product warranty will be voided. It is critical for proper product performance that surface preparation and application procedures are followed.

It is suitable for metal coating in various heavy anti-corrosion fields. It is suitable for rust prevention and corrosion prevention of large steel structure, bridge, ship, tower crane, tower, oil storage tank, truck fork, lifting boom and other steel components.

Details

Technical parameters

Color:Various colors

Solids:55±3%

Glossy:No light

Drying time (25'°C):at 1 hour

Actual 24 hours

dryer

Film hardness (70-80℃) Completely cured 7 days.

2 hours of hands-on work

Paint film adhesion H

Level 1

Paint film flexibility

Paint film impact resistance

Salt fog resistance 2mm

50cm. kg

Theoretical coating rate 300h

8e1/kg (40μm dry film)

Construction method Proportioning

Construction method Component A:Component B=2:1

Air spray/airless spray

thinner

Dilution amount Clean water

5-15% of the total

Nozzle size

Spraying pressure 1.5-2.5mm

Applicable period 0.4-0.6Mpa

3h (at 20°C)

Advantages:

1.Low VOC; low odor

2.HAPS free

3.High durability

4.High resistance to abrasion

PRODUCT MIXING:

This product comes pre-packaged by weight. Kits should be mixed in their entirety. If partial kits are to be used, refer to the front of this technical data for proper weight mix ratios. After the two parts are combined, mix well with slow speed mixing equipment such as a jiffy mixer until the material is thoroughly mixed and streak free. This product is an emulsion product and should be mixed well before using. If you choose to mix by hand, it is recommended to mix thoroughly for several minutes.

Coating data

Main color:iron red/gray/black

Gloss:matte

The mass solid contains:40%

Typical thickness dry film :(40-60) microns

Theoretical coating rate:6-7m2 /Kg single pass

The actual coating rate takes into account the appropriate loss factor

Coating methods:Airless spraying, air spraying, brush coating, roll coating

Main characteristics

1. Like all epoxy paint, powder and fade will occur when exposed to atmospheric environment, but these phenomena have no effect on the overall corrosion resistance.

2. Apply the product by brush or silver coating, it may be necessary to apply multiple passes to obtain the specified dry film thickness. Excessive coating thickness should be avoided, and the wet film thickness of a film formation should not exceed 150μm.

3. High salt spray resistance, excellent corrosion resistance, excellent oil resistance, water resistance, salt water resistance, solvent resistance: the paint film is tough and dense, and the substrate has good adhesion. The thickness of the paint film is above 85 microns, and the corrosion resistance is better.

4. Low temperature curing. This product is a water-based system, not suitable for low temperature environment, the temperature below 10C is not recommended for construction, because the product below 10C conditions, can not be fully cured, below 0C products will freeze, can not be used.

Construction description

1. Clean the oil, rust, old patent leather and other dirt on the surface of the substrate before painting to ensure that the surface of the substrate is clean and dry.

2. Grinding wheel is used to remove welding bumps, spatter, and hardened layer on the workpiece surface. All free edge acute angles after gas cutting, shearing or machining should be polished to R2.

3. Sand blasting to Sa2.5 level or power tool cleaning to St2 level, construction within 6 hours after sand blasting.

4. Brush painting and spraying can be used for construction, and the paint should be stirred evenly before painting. If the viscosity is high, an appropriate amount of deionized water can be added, and the amount of water added should not exceed 10%, and it should be stirred while adding to ensure that the paint is uniform.

5. Maintain good ventilation during construction, and do not recommend construction when the ambient temperature is lower than 5 ° C or the humidity is greater than 85%.

6. Rain, snow and fog weather can not be constructed outdoors, such as construction, can be taken to protect the paint film by covering it with tarpaulin.

Storage and transportation

1. The product should be sealed and stored in a dry and well-ventilated warehouse with a storage temperature above 5 ° C and below 35 ° C to prevent direct exposure to water and sunlight, isolate the fire source, and stay away from the heat source.

2. If the product meets the storage conditions, the storage period is one year from the date of production, and the storage period can be tested beyond the storage period. If it meets the standards, it can still be used.

3. During the transportation process, the product should be prevented from cold, rain and sunlight exposure, and should comply with the relevant provisions of the transportation department.

Surface treatment

1. All surfaces to be coated shall be clean, dry and non-polluting, all surfaces shall be evaluated and treated according to ISO8504:1992, and grease shall be removed according to the requirements of the SSPC-SPI solvent cleaning standard.

2. The areas that have been coated with primer and have peeling and damage are treated according to the necessary standards, and these parts are recoated with primer before coating. The steel structure, welds and damaged areas of the pre-painted workshop primer should be sandblasted, polished or sanded. If the workshop primer falls off on a large scale, it needs to be fully treated.

Notes

1.24 hours prior to installation, store material between 70°F to 75°F (21°C to 24°C) for best results

2.Substrate and ambient temperature should be between 70°F to 90°F (21°C to 32°C) for best results

3.For best results humidity should be between 50% and 70% R.H.

4.Moisture content should not exceed 3% for concrete substrates and 15% for wood substrates

5.Allow for proper joints in substrates and do not overcoat joints

6.Do not thin the coating

7.After surface preparation and prior to applying primer, use masking tape to tape off any areas that are not to be coated. Note: pay special attention to joints, bolt holes, areas of contact or abrasion, or hinges: tape off any area that does not require coating. Important: prior to material drying, remove tape.

8. This product should not be mixed with any oil-based paint or organic solvent.

9. the curing agents used for different paints should not be mixed.

10. It is forbidden to contact with acid and alkali in the process of paint preparation and coating.

11. Wear the necessary protective equipment at the construction site.

12、After the curing agent is prepared for this series of products, it should be used within the applicable period under the condition that there is no pollution.

FAQ

Q. Are you factory or trading company?

A. We are a factory located in Fuan city, Fujian province, China .

Q. Are all colors are same price?

A.No, the price are different depend on the texture, availability, Ingredients and So on.

Q. Can you provide samples for quality checking before placing an order?

A. Samples are available upon request, but the shipping cost should be paid by customer.

Q. Is there a discount?

A. The discount will be given by the quantity.

Q. How about delivery time?

A. About 7-15 days after payment confirmed.

Q. What kind of payment terms you can accept?

A. We accept T/T, LC, Western Union and Paypal.